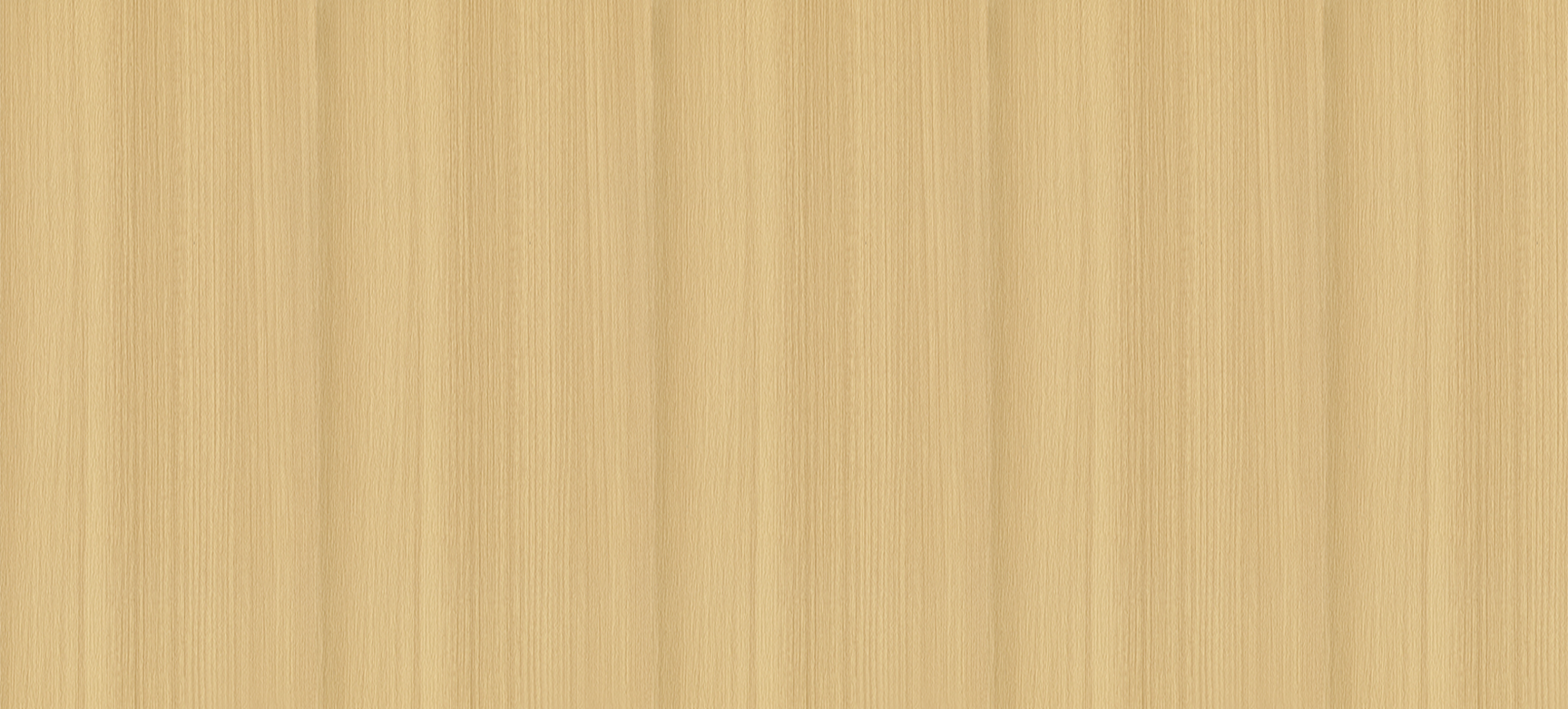

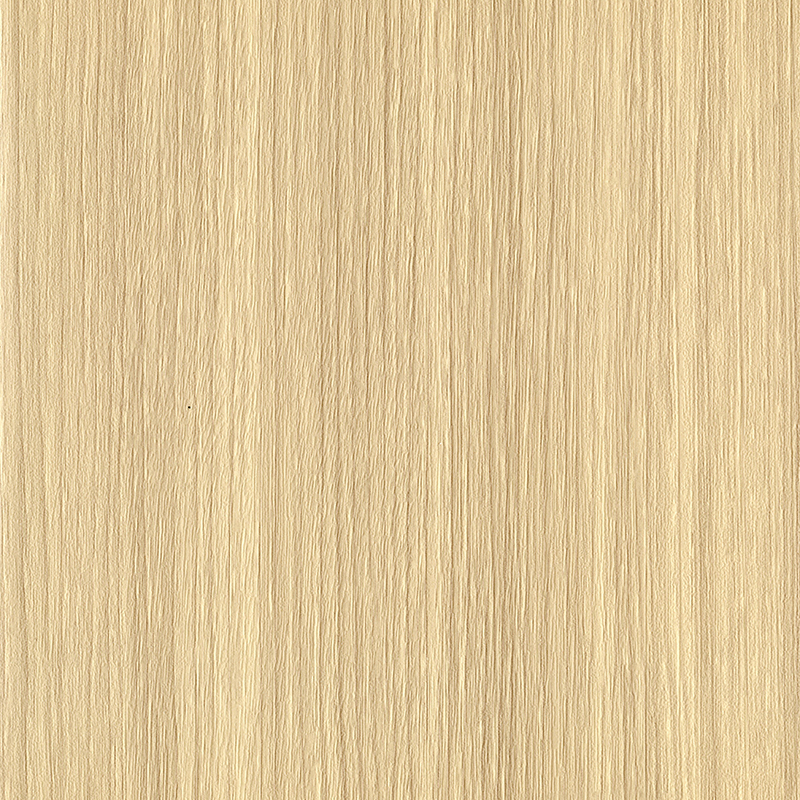

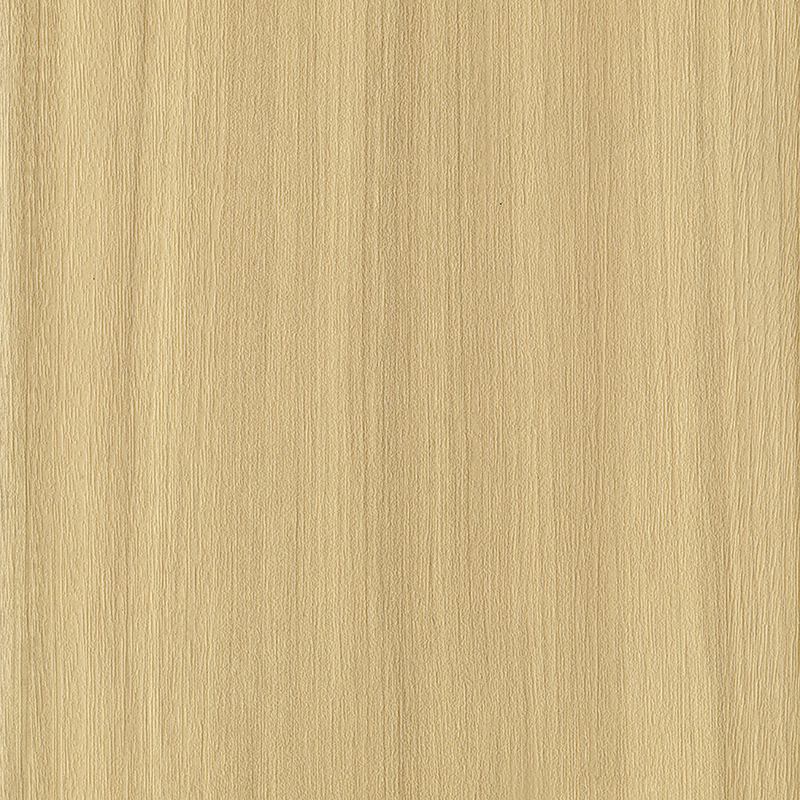

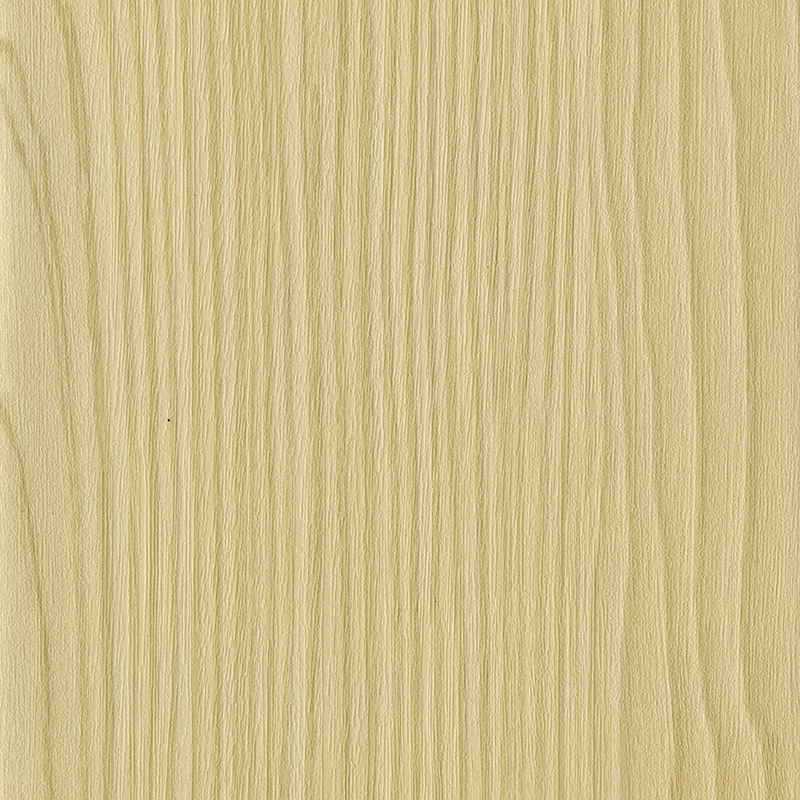

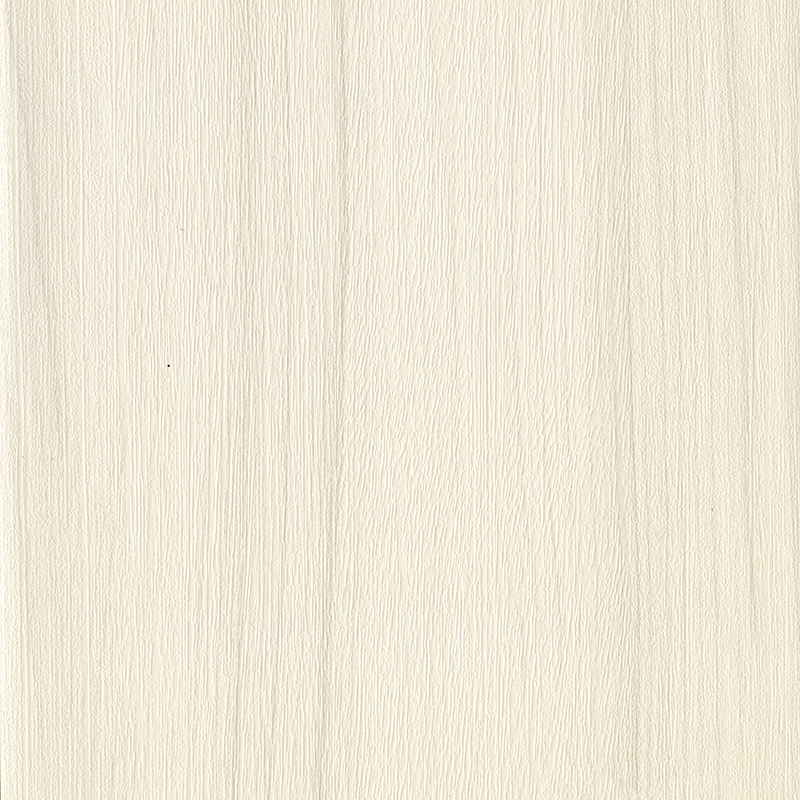

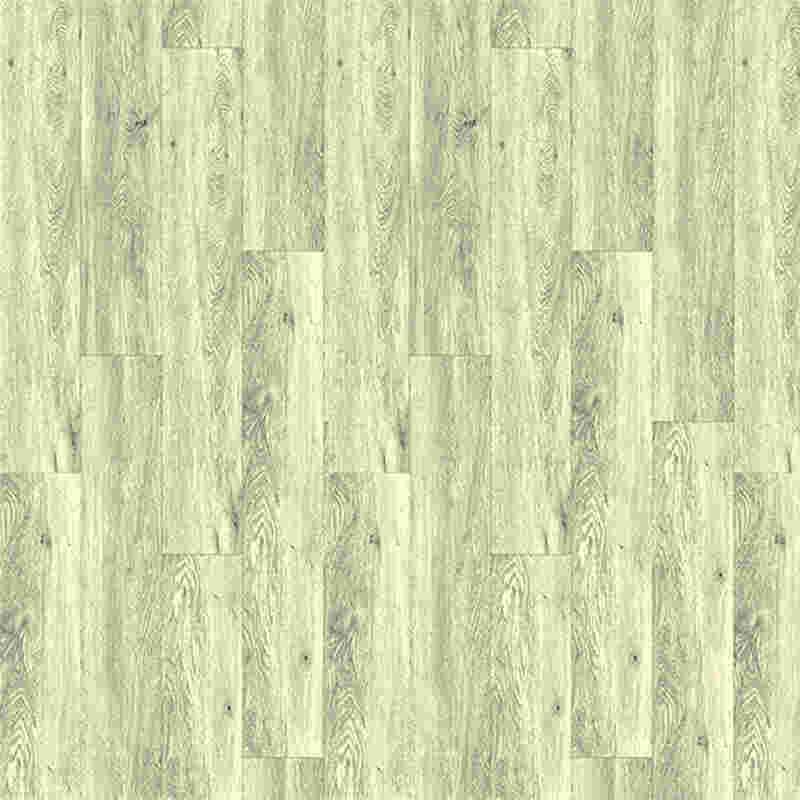

1: Description:

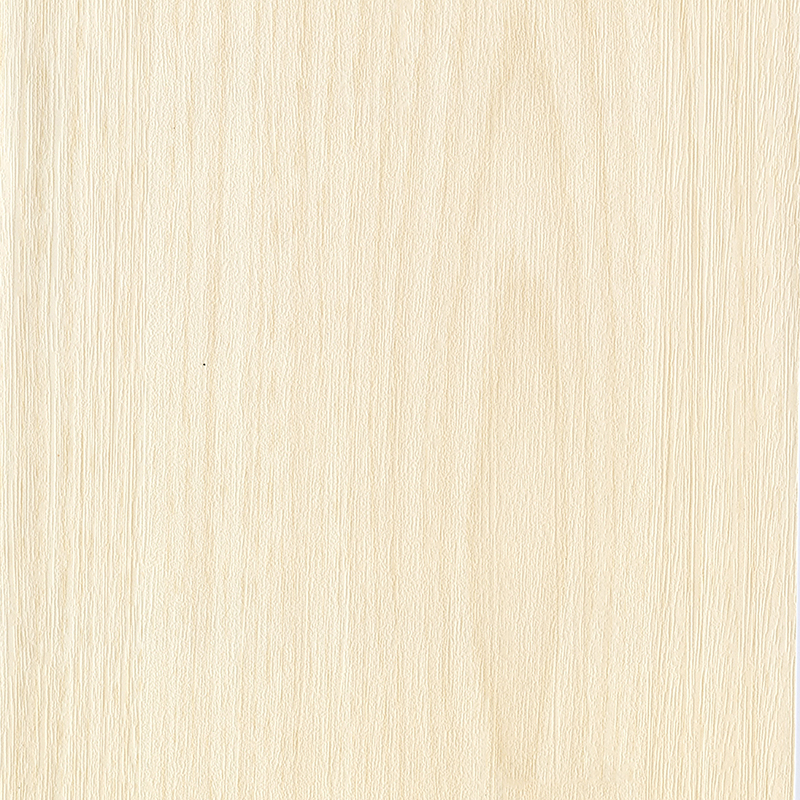

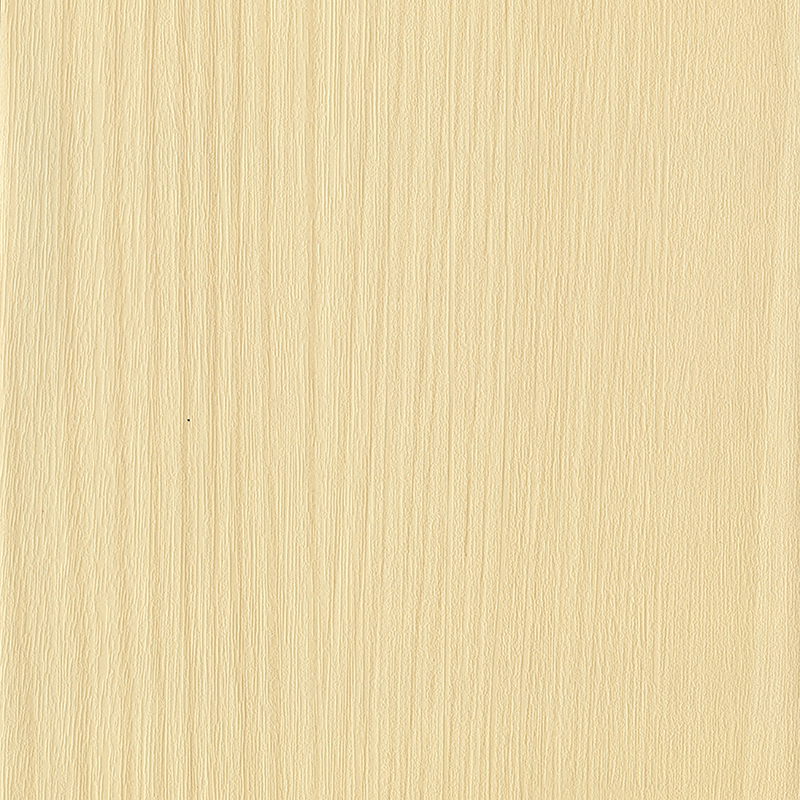

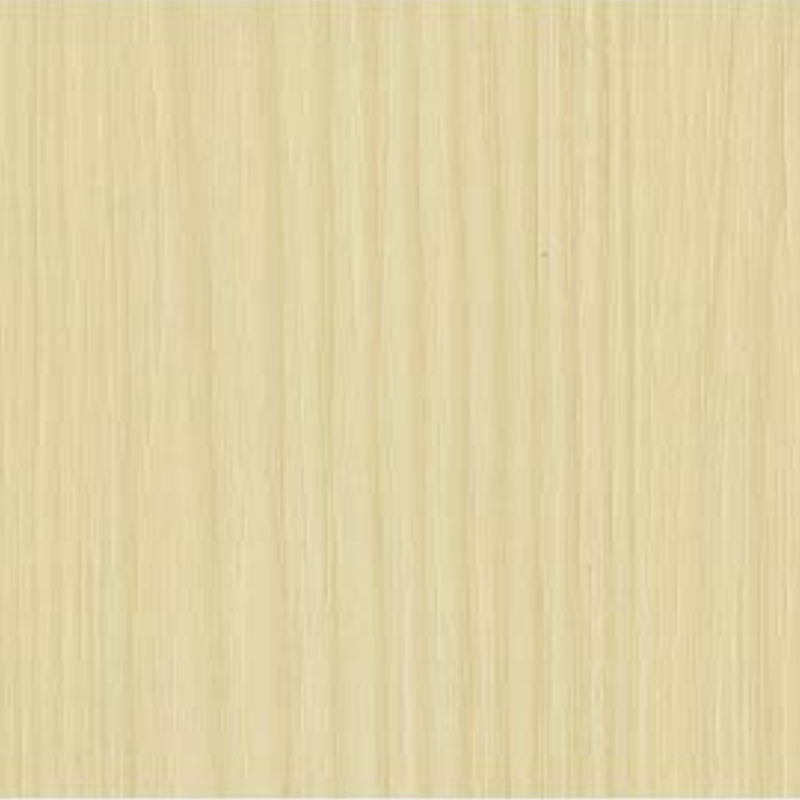

exterior wall cement wood-grain Panels is a Class A non-combustible cladding panel made with cement as the primary binder, blended with quartz sand, fiber reinforcement and specialty additives, then processed to replicate natural wood-grain textures. Combining the high strength and durability of cement products with the warm aesthetics of timber, it is widely specified for contemporary façade applications, delivering both fire safety and visual appeal.

2: Core Composition & Structure

2.1: Main Composition--

Binder: High-strength Portland cement blended with supplementary cementitious materials (fly ash, slag powder) to enhance density and long-term durability.

Aggregate: Refined quartz sand and lightweight ceramsite are used to maintain strength while reducing panel weight.

Reinforcement: Alkali-resistant glass fibers and cellulose fibers are uniformly dispersed throughout the matrix, increasing crack resistance and toughness.

Additives: a blend of water-repellent agents, plasticizers, set retarders, and wood-grain texture enhancers that optimize both performance and appearance.

2.2: Structure Features

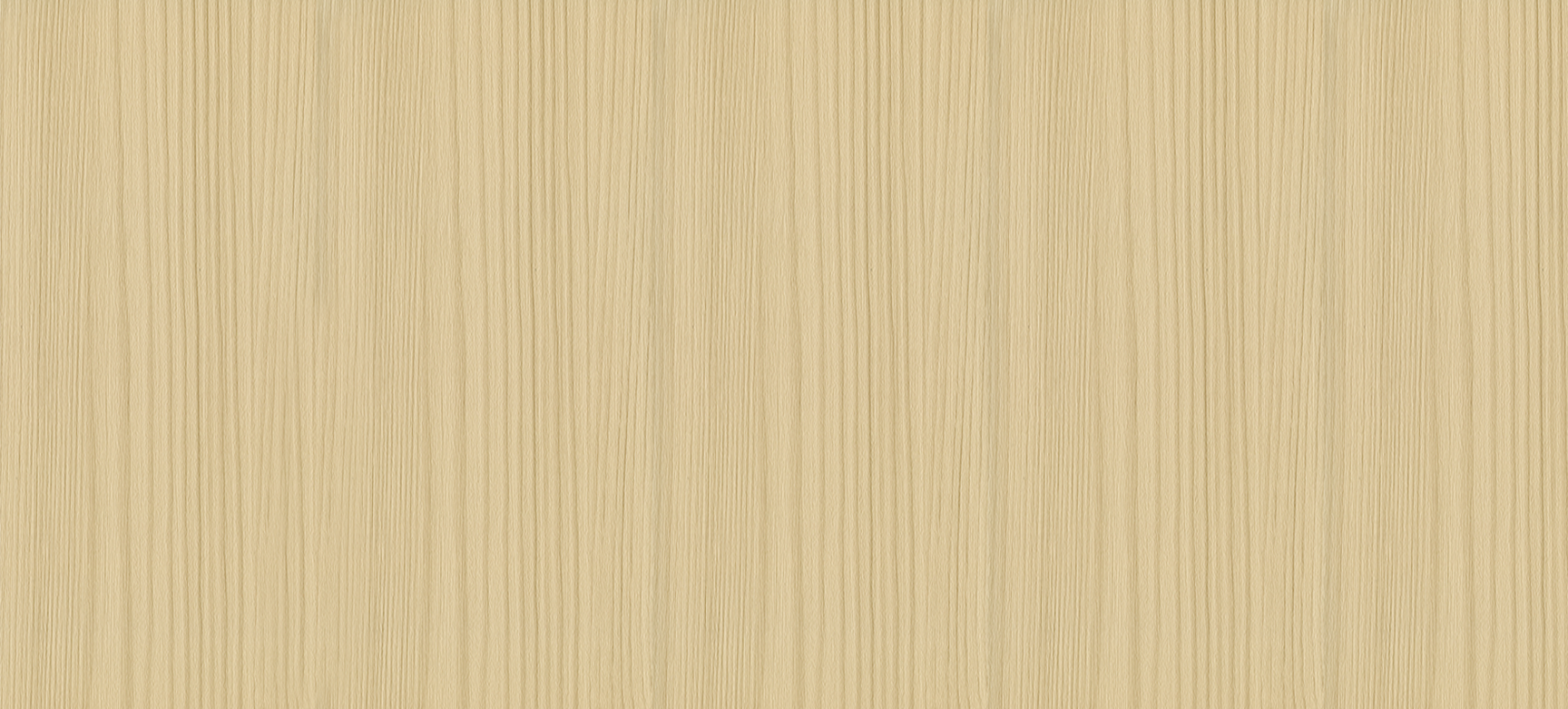

Panel Construction: Standard thickness ranges from 18–30 mm. The surface is imprinted with realistic wood-grain via mold-pressing or roll-embossing, while the back features dovetail grooves or anchor holes for easy mechanical fixing.

Internal structure: Hydration products of cement interlock with aggregate to form a rigid skeleton, while interwoven fibers provide reinforcement, creating a dense, high-strength three-dimensional system.

русский

русский عربى

عربى Español

Español